Objectives & Challenges

Our client was struggling with poor traceability and a lack of control over maintenance activities. The main objectives of the project were:

- Ensure all planned maintenance activities were executed through Work Orders

- Implement a structured backlog management methodology to enhance planning and task execution

Client Pain Points

- Maintenance requests were submitted through disorganized channels: verbal communication, text messages, emails, phone calls, and non-integrated internal tools

- Tasks were assigned informally, without proper tracking or documentation

- Frequent last-minute changes during maintenance shutdowns disrupted the planned execution

- A reactive maintenance culture dominated operations — more firefighting than strategic planning

- Ineffective communication across teams involved in the maintenance process

- Excessive time spent on planning that yielded low-impact results due to lack of prioritization and task criticality analysis

Solution Implemented

To address these challenges, we implemented structured and practical solutions aimed at optimizing maintenance management:

- Clearly defined inputs for the planning and control process

- Customized maintenance schedules by function and area

- Standardization of work order types, statuses, and prioritization criteria

- Detailed departmental maintenance plans outlining activity types, frequency, and estimated time

- Implementation of a backlog monitoring tool to identify inconsistencies such as orders with no due date, no responsible party, or excessive time open

- Training for Maintenance, Production, Safety, Quality, Environmental, and Engineering teams on how to create Work Orders

- Creation of tutorials and standardized operating procedures to ensure consistency

- Establishment of efficient workflows to systematize and control all processes

Roadblocks

During implementation, we encountered two major barriers that required specific strategies to overcome:

- A deeply rooted reactive maintenance culture focused on “firefighting” rather than proactive planning

- Resistance from the local union

Results

The implementation led to significant improvements across the client’s maintenance operations:

- 300% increase in work orders created directly by shop-floor technicians

- Within three months, 35% of technicians had created at least one work order

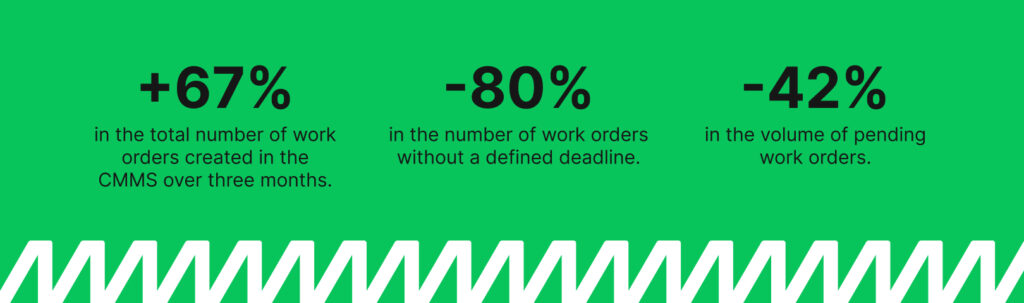

- 67% increase in total work orders created in the CMMS in three months

- 80% reduction in work orders with no defined due date

- 42% decrease in the volume of pending work orders

- Over 100 people trained

- Weekly maintenance planning culture successfully introduced

- A detailed diagnosis was completed for a previously unmapped area, expanding the project scope

Benefits

This success case shows how implementing a structured maintenance management system can transform operations. By systematizing the registration, planning, and scheduling of maintenance activities — and improving team engagement — we achieved substantial outcomes, including:

- Increased asset availability and maximized uptime

- Improved efficiency across all stages of the maintenance process

- Clear and effective communication between teams, fostering integrated collaboration

- Better data quality and operational monitoring, enabling more informed decision-making

- A fully integrated database offering unified, reliable insight for ongoing optimization