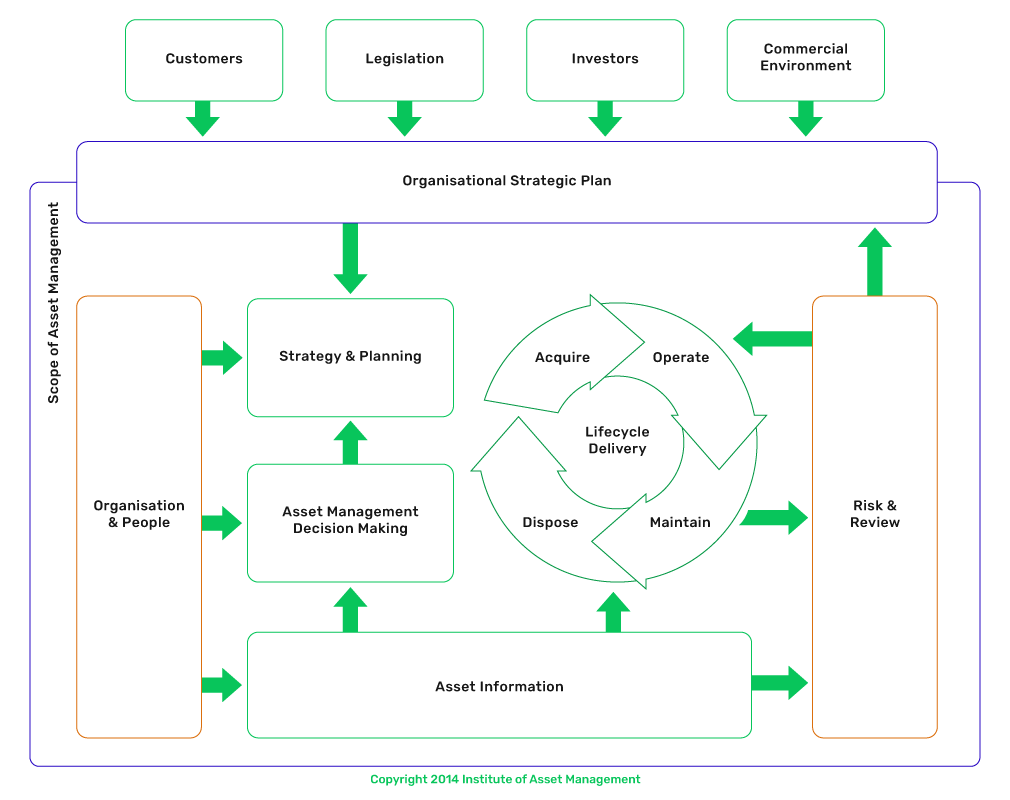

Building a solid and reliable asset management system is essential to ensure the technical, operational, and financial performance of assets throughout their lifecycle. At Emet, we support organizations in conducting maturity assessments based on ISO 55000 and the GFMAM (Global Forum on Maintenance and Asset Management) guidelines, identifying real improvement opportunities and developing consistent action plans focused on results and sustainability.

We believe that well-structured data, standardized processes, and clearly defined responsibilities — established through tools such as the SAMP (Strategic Asset Management Plan), AMP (Asset Management Plan), and Asset Management Policy — are essential to ensure that assets fulfill their intended function with the best cost-benefit ratio over their full lifecycle.

We also promote integration across all departments involved in asset lifecycle management — including maintenance, operations, supply chain, engineering, HR, finance, and others — to strengthen asset governance. We establish clear rules of interaction, well-defined responsibilities, and unified technical criteria for decision-making, promoting alignment across the organization. This synergy is key to ensuring efficient, safe, and results-oriented asset management.

Reliability Engineering

Asset reliability is one of the main drivers of productivity, operational costs, and industrial safety. Our goal is to help your company move beyond reactive or time-based maintenance and adopt a strategy focused on reliability and actual asset performance.

We support our clients in building a strong foundation for Reliability Engineering through activities such as:

- Equipment criticality analysis

We define technical priorities based on factors such as production impact, safety, environmental risks, and failure cost. - FMEA and root cause analysis

We identify potential failure modes, root causes, and effects to develop more accurate and preventive maintenance plans. - Optimization of maintenance plans and component replacement

We review and adjust replacement and preventive maintenance plans based on historical data, recurring failures, actual operating conditions, and ideal frequency. - Spare parts optimization

We analyze consumption data, criticality, and lead times to ensure part availability without overstocking or tying up unnecessary financial resources.

Reliability is built on well-documented data, applied engineering, and a maintenance system that learns from failure. Our role is to turn those pillars into real business value — reducing unplanned downtime, increasing operational predictability, and strengthening a culture of continuous improvement.