Industrial maintenance is more than just fixing machines. It is a strategic function for companies that depend on physical assets to produce, deliver services, or transform inputs. Without it:

- unplanned downtime erodes productivity;

- emergency costs quickly blow up budgets;

- risks to safety, product quality, and reputation increase.

On the other hand, a mature maintenance strategy:

- improves equipment reliability and availability;

- reduces waste and rework;

- allows cost predictability;

- creates positive impacts on sustainability and safety.

In this guide, we explain the main concepts, types of maintenance, strategies that reflect different stages of maturity, and the tangible benefits of a world-class approach.

What is Industrial Maintenance?

Industrial maintenance is the set of practices, processes, and technical and human resources aimed at ensuring that equipment, machines, facilities, and infrastructure operate reliably, safely, and cost-effectively throughout their lifecycle.

It includes preventive, corrective, predictive, prescriptive, proactive, and autonomous activities, as well as asset management, planning, and control.

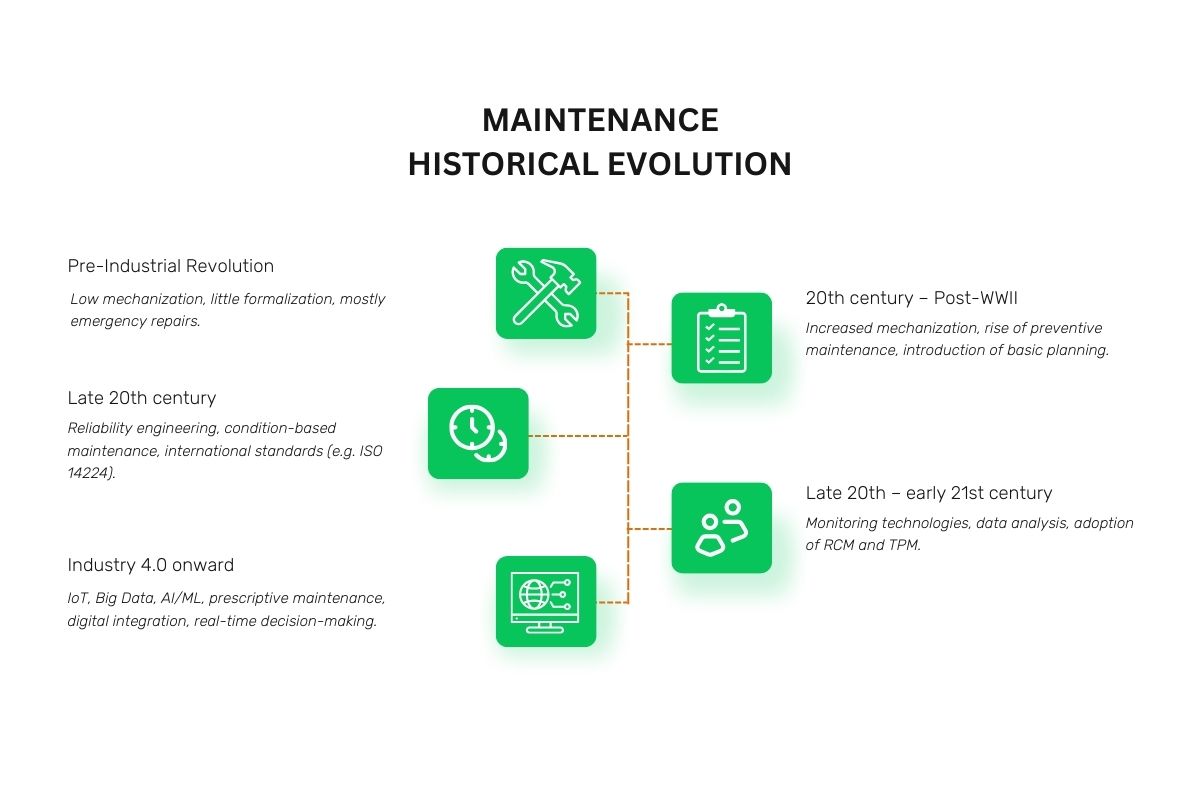

Over time, maintenance has evolved significantly. What was once seen as a collection of improvised repairs has become a strategic discipline, supported by advanced technology and capable of anticipating failures before they occur.

Before the Industrial Revolution, maintenance was mostly artisanal, with little mechanization and no formal processes. Interventions happened almost exclusively as emergencies — only when something had already gone wrong.

In the 20th century, especially after World War II, industrial mechanization accelerated and the concept of preventive maintenance emerged. Basic planning was introduced, giving companies more predictability.

In the second half of the century, international standards (such as ISO 14224) and the growing adoption of reliability engineering helped consolidate concepts like condition-based maintenance. Maintenance management began to take on a more technical and strategic role.

By the turn of the 21st century, new technologies transformed the field: continuous monitoring, data analysis, and methodologies such as RCM (Reliability-Centered Maintenance) and TPM (Total Productive Maintenance) became part of industrial best practices, linking maintenance directly to productivity.

In the era of Industry 4.0, the landscape evolved even further. Today, IoT, Big Data, Artificial Intelligence, and Machine Learning enable prescriptive maintenance, combining historical and real-time data. This digital integration ensures higher efficiency, cost reduction, and most importantly, failure anticipation — consolidating maintenance as one of the pillars of industrial competitiveness.

Historical Evolution

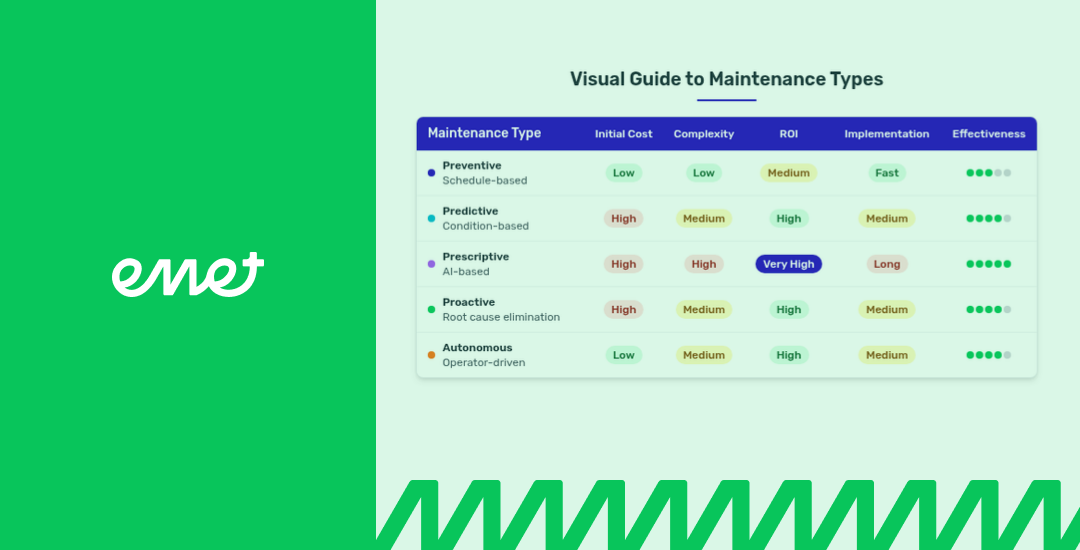

Types of Industrial Maintenance

Different types of maintenance can be applied depending on equipment criticality, organizational maturity, and available resources. Understanding each one is essential to reduce costs, increase asset reliability, and ensure competitiveness.

Corrective Maintenance

Corrective maintenance occurs after the equipment has failed. Its goal is to restore functionality. It can be:

- Scheduled: the failure has occurred, but there is time to organize the intervention. Teams can plan how to execute the repair, what parts to use, which tools are needed, and how to ensure safety.

- Emergency: the failure happens unexpectedly, requiring immediate action. Teams must improvise, often facing high costs, production impacts, and additional risks.

Corrective maintenance may be acceptable for low-criticality assets where the cost of prevention outweighs the cost of repair. However, relying solely on it leads to hidden costs, productivity losses, and greater stress on teams.

Cost and risk impacts

| Aspect | Scheduled | Emergency |

|---|---|---|

| Intervention cost | lower than emergency, but still significant | usually very high: overtime, production losses, collateral damage |

| Risk of secondary failure | moderate | high (additional damage may occur) |

| Logistics (parts, workforce) | organized | improvised |

| Downtime | lower if prepared | generally longer and unpredictable |

Preventive Maintenance

Unlike corrective, preventive maintenance is scheduled in advance, based on time intervals or usage (operating hours, mileage, cycles, etc.). It includes inspections, lubrication, adjustments, and planned part replacements.

The goal is to reduce the probability of failure and keep assets running at expected performance. Preventive work is both scheduled (when) and planned (how).

Advantages

- Reduces unexpected failures.

- Improves cost predictability.

- Minimizes unplanned downtime.

- Enables better allocation of maintenance resources.

Challenges

- May generate unnecessary work if intervals are not optimized.

- Requires reliable history, data, and planning discipline.

- Demands spare parts inventory.

- May not catch sudden or unpredictable failures.

These challenges highlight why it’s vital to return to core principles. Learn more in Back to the Basics: Unveiling the Power of Fundamental Maintenance Practices.

Predictive Maintenance

Predictive maintenance addresses the limits of preventive strategies. Instead of relying solely on time intervals, it uses condition monitoring and data analysis to identify failure signs in advance.

By monitoring critical variables (vibration, temperature, noise, oil analysis, electrical discharge, etc.), companies can detect degradation and act before failure occurs.

Benefits

- Fewer unnecessary interventions.

- Reduced downtime.

- Maximizes component life.

- Increases reliability.

Limitations

- High initial investment in sensors and monitoring systems.

- Requires data analysis expertise.

- Potential for false positives or false negatives.

- Complex to scale across all assets.

Prescriptive Maintenance

Prescriptive maintenance is considered an evolution of predictive. Instead of only predicting when a failure will occur, it also recommends what to do, when, how, and with which parts.

By using AI, Machine Learning, and advanced analytics, prescriptive systems turn data into actionable recommendations. For example, identifying that a compressor is losing efficiency and suggesting a filter cleaning or recalibration before failure.

Benefits

- Anticipates failures with actionable recommendations.

- Optimizes resource usage (parts, labor, downtime).

- Strong integration with reliability and asset management strategies.

- Significant reduction in unplanned downtime and corrective costs.

- Enables automation of decisions and faster responses.

Limitations

- High upfront cost and complexity of integration.

- Dependence on quality and volume of data.

- Requires specialized data science and reliability skills.

- Risk of overreliance on algorithms without continuous validation.

- Needs a mature organizational culture to adopt prescriptive insights.

Proactive Maintenance

Proactive maintenance aims to eliminate the root causes of failure. Using methodologies like RCA (Root Cause Analysis) and RCM (Reliability-Centered Maintenance), it focuses on why failures happen and how to prevent recurrence.

Example: if a motor repeatedly fails due to seal issues, proactive maintenance investigates lubrication, alignment, vibration, and design. Solutions may include material upgrades or process adjustments.

Benefits

- Reduces recurring failures.

- Increases asset reliability.

- Extends equipment life.

- Cuts long-term costs.

- Improves safety.

Limitations

- Requires deep technical analysis.

- Higher upfront investment.

- Longer implementation time.

- Demands reliable data.

- Complexity increases with system size.

Autonomous Maintenance

Autonomous maintenance is a core pillar of TPM (Total Productive Maintenance). It empowers operators to perform basic care on their equipment, such as cleaning, lubrication, visual inspections, and minor adjustments.

The goal is to increase operator ownership, detect early abnormalities, and relieve the maintenance team of simple tasks.

Benefits

- Increases operator engagement and ownership.

- Prevents simple failures through routine care.

- Improves communication between operations and maintenance.

- Reduces maintenance team workload.

- Reinforces continuous improvement culture.

Limitations

- Requires upfront training and onboarding.

- Depends on operator discipline and consistency.

- Risk of inconsistent execution without clear standards.

- Needs supervision and audits to ensure effectiveness.

- May face cultural resistance where operations and maintenance are siloed.

Maintenance Management and Organizational Maturity

Not all companies are at the same stage of maturity in maintenance management. Some still operate reactively, constantly firefighting, while others have adopted advanced monitoring, AI, and asset management strategies.

The choice of strategy depends on:

- equipment criticality (impact of failure: financial, environmental, safety);

- available resources (financial, human, technical);

- organizational culture (preventive vs reactive mindset);

- quality of historical data and technology adoption.

Maturity model overview

| Maturity level | General characteristics | Dominant strategies | Improvement opportunities |

|---|---|---|---|

| Initial / Reactive | Little planning, high emergency costs, weak failure history, firefighting culture. | Unplanned corrective; some ad hoc preventive. | Formalize failure records, build history, establish maintenance planning and control (PMC). |

| Planned / Preventive | Scheduled preventive work, inspections, controlled parts inventory, basic KPIs. | Preventive + planned corrective; some autonomous maintenance. | Optimize intervals, introduce condition monitoring, improve spare parts logistics, train staff. |

| Monitored / Predictive | Real-time or near real-time monitoring, condition analysis, reliability KPIs. | Predictive on critical assets, data-driven preventive, proactive. | Improve data quality, reduce noise, calibrate alerts, expand prescriptive. |

| Advanced / World Class | Strong reliability culture, robust RCA/RCM, prescriptive, autonomous (TPM), continuous improvement, WCM. | Prescriptive + proactive + autonomous integrated; full lifecycle asset management. | Expand digitalization, integrate with business strategy, advanced KPIs, simulations, benchmarking. |

These maturity levels become actionable when supported by structured routines. Dive deeper into the comprehensive guide to maintenance planning and scheduling.

World Class Maintenance: The Next Level

World Class Maintenance (WCM) represents the advanced stage of asset management maturity. After understanding and applying corrective, preventive, predictive, prescriptive, proactive, and autonomous approaches, companies reach a point where maintenance becomes a competitive advantage.

At this level, processes are highly integrated, teams are engaged, data is fully leveraged, and continuous improvement is part of daily culture.

Tangible benefits include:

- Reliability & Availability: longer uptime, fewer unexpected failures, reduced emergency stoppages.

- Cost reduction: fewer emergencies, optimized spare parts usage, predictable budgets.

- Safety: safer equipment reduces accidents and builds operator confidence.

- Product quality: stable processes produce less variation and waste.

- Sustainability & energy efficiency: well-maintained equipment consumes less energy and reduces waste.

- Culture & engagement: operators and technicians feel ownership, driving autonomous maintenance and continuous improvement.

Conclusion

Throughout this guide, we saw how the historical evolution of maintenance — from basic corrective repairs to prescriptive, proactive, and autonomous practices — proves that the more mature asset management becomes, the greater the reliability, safety, and efficiency of operations.

Applying the right mix of maintenance types, combined with team engagement and technology integration, is what enables companies to achieve world-class performance. This approach not only reduces costs and prevents unexpected failures but also strengthens continuous improvement, sustainability, and quality.

And the results speak for themselves: companies that advance in maturity can reduce total maintenance costs by up to 40%, achieve asset availability above 90–95%, and improve KPIs such as MTBF and MTTR by up to 50%.

Investing in world-class maintenance means investing in the future of your plant: more reliable equipment, more efficient operations, and engaged teams. At this point, maintenance stops being just support — it becomes a true competitive differentiator, transforming industrial performance.

To secure leadership buy-in and amplify these results, communication is key. See Mastering Maintenance Narratives: Tips for Effective Communication.

Want to take your operation to the next level? Explore more articles and case studies on Emet’s blog and learn how to elevate your maintenance maturity.