Introduction

In an era of accelerated innovation and growing demand for efficiency, industrial maintenance faces complex challenges. Change is inevitable—whether it’s the introduction of new assets, implementation of technologies, or process restructuring. The key lies in how those changes are led. In this article, we explore how change management in maintenance, when well-structured and aligned with ISO 55000, can turn resistance into engagement and deliver real, lasting value.

What Is Change Management in Maintenance?

Change management is a structured set of practices designed to reduce resistance, increase engagement, and accelerate the adoption of new strategic directions. According to internationally recognized change methodologies, it goes far beyond training and communication. It involves preparing, guiding, and sustaining transformations that impact both people and processes.

Key focus areas include:

-

Creating urgency and meaning behind the change

-

Aligning leadership, sponsors, and frontline teams

-

Identifying and managing cultural and behavioral barriers

-

Building systems for active feedback and progress recognition

-

Reinforcing change through positive feedback loops and learning

In maintenance, this means ensuring new technologies, systems, structures, and work practices are understood, accepted, and internalized by those who operate and maintain them.

Historically, change was often rolled out top-down, with minimal technician involvement. This led to resistance, loss of productivity, and even project failure. Today, standards like ISO 55001 require any change affecting assets, people, or processes to be planned, evaluated, and executed in a controlled manner.

ISO 55001 dedicates section 8.2 to change management, emphasizing it as a key aspect of sound asset management.

What Can Go Wrong? Two Classic Pitfalls in Maintenance Change

1. Engineering Projects Rolled Out Without Maintenance Involvement

When capital investments are driven exclusively by engineering teams and maintenance is not included from the start, the result is often problematic. Maintenance inherits:

-

Poor maintainability (e.g., components requiring full disassembly)

-

Spare parts outside standard inventory

-

Machines using parts from multiple foreign suppliers, leading to high lead times

All of this could be avoided through early-stage alignment, where shared asset catalogs and existing inventory are considered during project design.

2. Not Listening to the People Who Operate

In some plants, operators used to return from holidays to find entire lines reconfigured. They’d attend a quick training session and be thrown back into operations—without ever having been consulted.

The outcome? Low morale, confusion, and loss of operational performance. When operators and technicians aren’t included in the change process, valuable insight is lost and resistance increases.

The Psychology of Change: How People React

Understanding how people respond to change is essential. Two useful frameworks illustrate this:

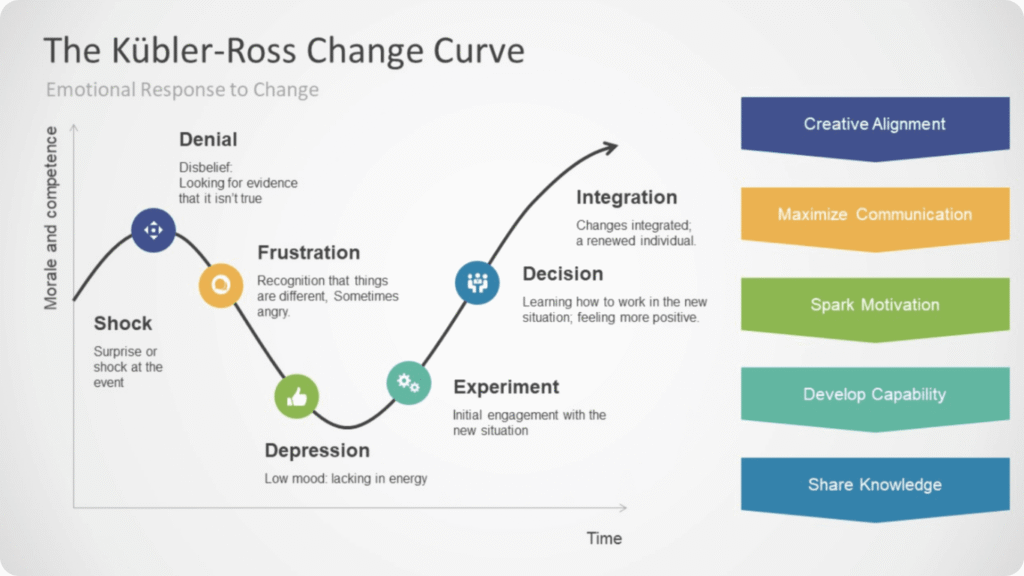

The Kübler-Ross Change Curve

Although originally developed to describe grief, the Kübler-Ross curve has become a powerful framework for understanding how individuals emotionally respond to organizational change. It maps the psychological journey people go through when facing new ways of working.

Each phase—shock, denial, frustration, depression, experimentation, decision, and integration—reflects fluctuating levels of morale and perceived competence. In the context of maintenance teams, these reactions are often triggered by new technologies, new procedures, or reorganizations that alter routines or responsibilities.

The role of leadership is to recognize where each person or team is on the curve and adjust their communication and support accordingly:

-

During shock and denial, people need clarity, empathy, and context—not technical overload.

-

In frustration and depression, managers should listen more than they speak. It’s a time to validate concerns and invite dialogue.

-

As individuals move into experimentation and decision, provide practical tools, hands-on support, and encourage early wins.

-

At integration, it’s essential to reinforce new behaviors, align incentives, and celebrate adoption milestones.

Ignoring these emotional dynamics can stall change efforts, while addressing them head-on creates trust, ownership, and long-term commitment.

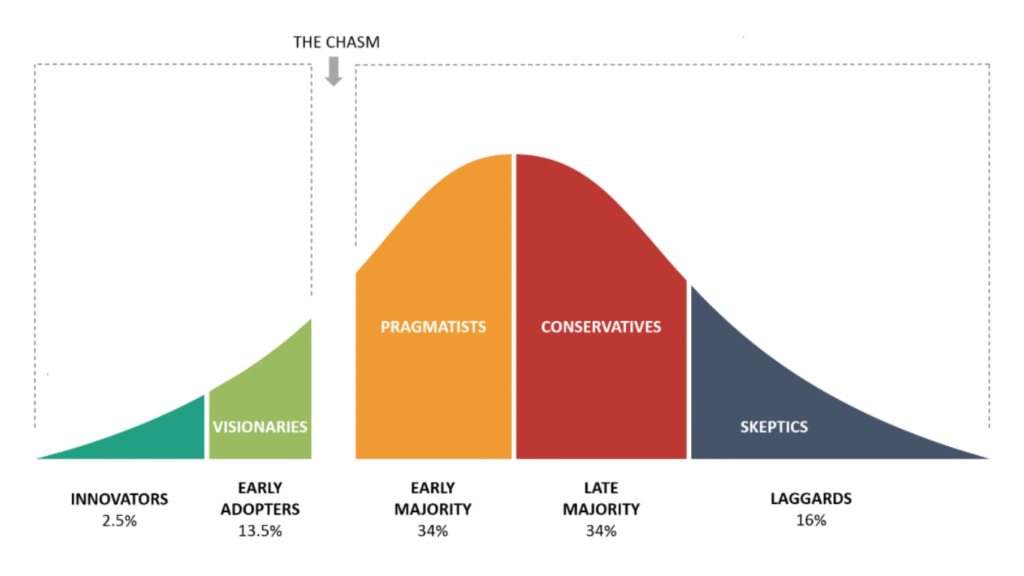

Rogers’ Innovation Adoption Curve

The Innovation Adoption Curve explains why change adoption is not uniform—and why one-size-fits-all approaches often fall short in industrial environments.

People adopt new processes, systems, or tools at different speeds based on mindset, experience, and perception of risk. Understanding this model allows maintenance leaders to roll out change more effectively:

-

Innovators love to test and explore. Involve them early in pilots and evaluations.

-

Early adopters bring credibility. Empower them to model behavior and share feedback.

-

Early majority waits for proof. Provide structure, clarity, and visible benefits.

-

Late majority adopts out of necessity. Offer reassurance, peer support, and steady reinforcement.

-

Laggards may resist until there’s no other option. Be patient, but firm—some may require personalized coaching or mentorship.

Rather than forcing uniform adoption, effective change leaders identify where people are along the curve and tailor their strategies. This targeted approach reduces resistance, builds momentum, and ensures a smoother transition across the entire operation.

How to Do It Better: Simple and Effective Practices

Based on globally recognized frameworks like ADKAR, PROSCI, and ISO 55000, here are practical steps for successful change implementation in maintenance:

-

Conduct gap assessments – Identify missing capabilities, culture gaps, or misaligned processes before launching the change

-

Interview your teams – Gauge readiness and uncover insights from the people who will live the change daily

-

Map risks and barriers – From technical complexity to behavioral challenges, anticipate and plan mitigation actions

-

Identify change agents – Find respected frontline leaders who can advocate for the change among peers

-

Free up key users – Dedicate time for strategic technicians to participate in pilots and testing instead of routine work

-

Secure leadership sponsorship – Ensure visible support from senior leaders to build credibility and remove resistance

-

Use structured communication – Keep the message clear, consistent, and contextual to reduce fear and confusion

-

Celebrate quick wins – Showcase early successes to generate momentum and reinforce desired behaviors

Benefits

Implementing structured change management in maintenance delivers tangible value:

-

Improved reliability – Smoother transitions with fewer breakdowns

-

Increased safety – Better planning reduces operational risk

-

Efficiency – Less rework and fewer delays during implementation

-

Team engagement – People feel part of the process rather than victims of it

-

Cultural maturity – Change becomes part of the improvement cycle, not a disruptive event

Conclusion

Change management in maintenance is not just a support function—it’s a strategic enabler. When well-executed, it protects your assets, empowers your workforce, and helps your organization evolve smoothly.

At Emet, we embed these practices into every transformation project we lead. From assessing readiness and engaging the right stakeholders to guiding change through structured frameworks, our approach ensures adoption, engagement, and lasting impact.

You can check out our real-world case studies in the Success Cases section of our website. If you’re preparing your maintenance team for a change initiative and want to do it right from day one, get in touch.