In the dynamic world of industrial maintenance, where innovation often takes the spotlight, the enduring strength of mastering the basicscan’t be overstated. Drawing from years of diverse roles within maintenance, from intern to management, as a Maintenance Consultant, I’ve witnessed the industry’s inclination towards cutting-edge solutions.

In this article, we redirect our focus to the essentials, delving into ten often-overlooked core aspects of industrial maintenance. Join me in rediscovering the simplicity and effectiveness of foundational practices, a timeless approach that promises not just cost savings but a robust foundation for success. Let’s shift the spotlight back to where it truly matters – the basics of industrial maintenance.

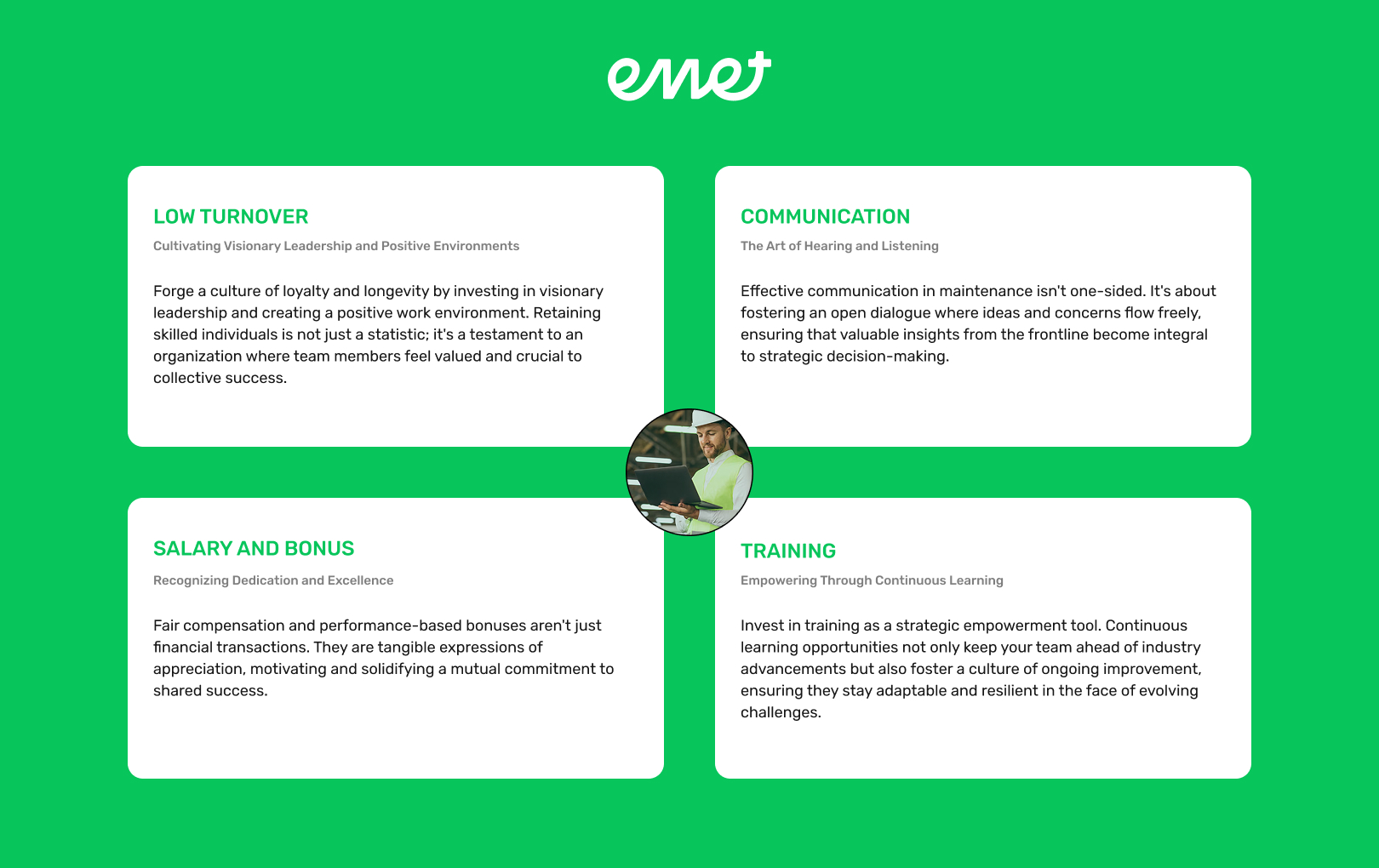

1: Elevating Industrial Maintenance Through Effective People Management

In the realm of industrial maintenance, success hinges on astute people management. Explore with me the key elements that transform a maintenance team into an enduring force.

2. Documentation Discipline: A Pivotal Element in Reliability

Documentation discipline stands as a pivotal element in the domain of industrial maintenance. This isn’t mere paperwork; it’s a strategic practice that elevates the reliability of your operations. Accurate and up-to-date records form a navigational guide, helping technicians navigate the intricate web of machinery intricacies. More than a historical archive, this documentation becomes a proactive tool, enabling precise troubleshooting and informed decision-making. As a record of deviations and solutions, it ensures that the knowledge gained over time contributes to ongoing improvements. In the absence of a robust paper trail, the reliability dance loses its rhythm, making documentation discipline an indispensable choreographer of a maintenance strategy geared for resilience and success.

3. Maintenance Planning & Scheduling: The Messi of Operational Excellence

Being an avid soccer enthusiast, I can’t help but draw parallels between the beautiful game and the intricate world of industrial maintenance. To me, the Maintenance Planner holds a role comparable to the soccer team’s number 10 — the playmaker. Just like the revered number 10 orchestrates every move, influencing the team’s strategy and connecting the dots, the Maintenance Planner is the cerebral force behind our operational game. Their experienced and knowledgeable approach to planning and scheduling mirrors the finesse of a skilled playmaker on the field. In the industrial realm, their strategic decisions minimize downtime, optimize resources, and ensure a seamless workflow. Much like a team relying on a Messi for brilliance on the soccer field, each maintenance team needs a Messi-like Maintenance Planner —experienced, knowledgeable, and capable of elevating the entire team toward operational excellence in the maintenance game.

These principles become even more practical when integrated into structured daily routines. Explore more in the comprehensive guide to maintenance planning and scheduling.

4. Preventive Maintenance Inspection (PMs): Foundation for Operational Resilience

Preventive Maintenance Inspection (PMs) assumes a pivotal role in the landscape of industrial maintenance, serving as the bedrock for operational resilience. Guided by the principles of Reliability-Centered Maintenance (RCM), PMs prioritize essential components, focusing on what truly matters for machinery health. The team’s collective experience becomes the compass, infusing vitality into the PM strategy. This isn’t a static procedure but a dynamic, living entity that demands continual updates to remain effective. Much like a well-orchestrated symphony, PMs harmonize the elements of maintenance, contributing to sustained success and the lasting operational health of the industrial environment.

5. Failure Analysis: A Snapshot of Wisdom and Collective Learning

Back in the days when cellphones weren’t our default cameras, I vividly recall a pivotal decision made by our Maintenance Leadership. Each crew was equipped with a digital camera, transforming us into makeshift journalists capturing the “scene of the crime.” The intent was profound – to arm ourselves with a tool that would enable us to document failures and collectively analyze them as a team.

Beyond just taking pictures, the essence of effective failure analysis lies in discovering the most fitting methodology. Like seasoned investigators, we delve into the root causes, meticulously examining the evidence at hand. Each captured image becomes a piece of the puzzle, a visual narrative that aids in unraveling the mystery behind the malfunction.

What makes this process truly invaluable is the collaborative approach. We analyze failures not just as individuals but as a crew, leveraging the diverse perspectives and trades within our team. It’s a collective exploration where the electrician, the mechanic, and the technician each bring their unique insights, enriching the depth of our analysis. This shared journey becomes a powerful opportunity for everyone to learn from failure, turning challenges into stepping stones for continuous improvement and the evolution of our maintenance practices.

For these learnings to gain traction across the organization, communication must be clear and intentional. Discover more in Mastering Maintenance Narratives: Tips for Effective Communication.

6. Standardization: Building Foundations for Excellence

In the relentless pursuit of operational excellence, the path of standardization emerges as a guiding light. The journey begins with identifying and standardizing critical tasks, a meticulous process that defines the beating heart of our maintenance operations.

Once the critical tasks are pinpointed, the focus shifts to empowering the crew through comprehensive training. This isn’t just about uniformity; it’s about arming every team member with the knowledge and skills necessary to execute tasks with precision.

The impact of standardization is profound and far-reaching. Beyond achieving consistency, it acts as a catalyst for safety, quality, and efficiency. Safety protocols become ingrained in every standardized process, ensuring a secure working environment. Quality is not just a goal but a standard met consistently across tasks, and efficiency becomes a natural byproduct, saving precious time in every operation.

7. Precision Lubrication: Safeguarding Machinery Vitality

Technical mastery is paramount. Visualize it as a healthcare protocol for machinery—preventing oil contamination, administering precise grease amounts, and using the correct grease formula. Just as we protect our bodies against impurities, maintaining a clean environment for lubrication safeguards machinery performance.

In this technical symphony, the maintenance crew assumes the role of skilled practitioners, comprehending the intricacies of machinery anatomy. Their precision ensures optimal lubrication, shielding against friction and wear. It’s not just about keeping parts moving; it’s a meticulous routine that safeguards machinery health, promoting operational longevity.

Credit: Noria – Tulsa OK USA

8. 5S / Housekeeping: A Personal Journey in Efficiency

In my journey through the maintenance realm, I’ve often found myself grappling with prolonged downtime, directly attributable to the disorganization of our shop. The direct correlation between a cluttered workspace and extended periods of inactivity became a poignant lesson.

Recognizing that full-scale 5S implementation may be a challenge, I’ve learned to embrace the mantra: if achieving 5S seems daunting, aim for 3S. Encouraging the team to foster a culture of cleanliness and organization, even without dedicated staff, has proven to be a transformative approach. The surprising revelation is that a well-organized space, cultivated through motivation rather than a significant investment, brings about numerous positive outcomes.

In my experience within the industrial maintenance domain, this personal journey underscores the profound impact of 5S or Housekeeping. It’s not just about tidying up; it’s about creating an environment where efficiency thrives, downtime dwindles, and results flourish—all with zero financial investment.

9. Predictive Maintenance: Empowering Your Team for Precision

While hiring a contractor is a commendable starting point, the journey into Predictive Maintenance (PM) also unfolds a powerful opportunity for in-house empowerment. Training and equipping your own employees to become inspectors can be a strategic investment in self-reliance.

By cultivating an internal cadre of inspectors, you not only enhance the skill set within your team but also foster a culture of ownership and expertise. This approach not only provides cost-effective alternatives but ensures that the knowledge and insights gained become an integral part of your organizational DNA.

In the landscape of industrial maintenance, choosing to empower your team for precision in predictive endeavors not only strengthens your operational resilience but establishes a foundation for sustainable success.

Credit: Exair Blog

Small budget?

Back in the days, when our budget was tight, I was working as an employee for a Steel Company, the leadership stumbled upon a practical gem. On those silent Sundays and holidays, when the machines took a breather, our utility operators took center stage. Among them, a seasoned operator with an extraordinary knack—he could pick up on air leaks with just his ears.

Armed with nothing but his acute hearing, he strolled through the facility, capturing the elusive leaks in pictures for a detailed report. As a maintenance planner, my mission was crystal clear – address those leaks promptly. The beauty of this tale lies not in a grand idea but in its simplicity. It’s a testament to how a keen ear, a camera, and a commitment to solving problems can turn a routine inspection into a savings success story, proving that efficiency often thrives in the simplest of solutions.

10. Spare Parts Management: Precision for Uninterrupted Operations

Spare Parts Management stands as the cornerstone in industrial maintenance, ensuring operational continuity with precision. A well-organized system minimizes downtime by having critical components readily available. Beyond immediate benefits, this approach extends equipment lifespan and optimizes maintenance costs. It’s the proactive shield against disruptions, embodying the technical finesse that transforms potential challenges into a seamlessly efficient working environment.

To connect these fundamentals with the broader spectrum of types and strategies of maintenance, check out the complete guide to industrial maintenance.

Let’s Fuel the Discussion and Elevate Your Maintenance Game!

- Join the Conversation: Your thoughts and experiences are invaluable. Share your insights in the comments below, and let’s create a dynamic exchange of ideas. Together, we can enrich our understanding and inspire innovation in the realm of industrial maintenance.

- Struggling to Implement These Fundamentals? Book a Free 1:1 Call: If you find yourself facing challenges in implementing these maintenance fundamentals, don’t navigate the journey alone. We’re here to help. Book a complimentary 1:1 call with us. Let’s discuss your specific hurdles and explore tailored solutions to elevate your maintenance practices. Your path to operational excellence starts with a conversation — schedule your call today.